| The Powder Coating

Process:

1)

All products or parts that arrive at our facilities regardless

of size or quantity, will be inventoried by our customer service

rep and our customer.  In the case of "mail orders"

letters describing detail and color will need to accompany the

products). In the case of "mail orders"

letters describing detail and color will need to accompany the

products).

All job's receive a "job order work tag sheet". This work

sheet will follow our customer's job from start to finish. The

sheet will track part count, blast time, outgassing of parts, degreasing

time, wash & racking time, powder coating, baking, packaging

& shipping, and misc time. This sheet also tracks color

choice, arrival time and approximant shipment date.

Why do we do all this? Because this helps us to keep track of

all aspects of your parts, we want our customers to get back

everything they sent us!

This also helps us to bill our customer the correct and fair

amount.

2)

Whatever your interest or need may be, from restoration, marine,

industrial, to show, the key to an excellent

finish, is proper surface preparation of your part.

Your parts may only require a chemical surface prep, or a pass

through our chemical wash tank.

They may need to be "out gassed" to remove impurities

trapped deep in the part. This is a "must" for many

used parts and castings.

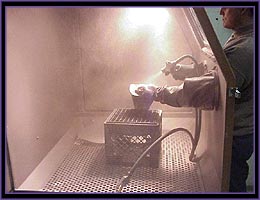

Your parts also may require more intense cleaning of the

surface, this is done by "media blasting" your parts,

using aluminum oxide or glass bead, then followed by a

"chemical pretreatment" and "bake dry

process" @ 275 degrees F for 15 min's.

The process needs, are based on the parts application and the

parts surface material.

All this surface prep is a "must" in providing an

excellent "bite" for the powder coating, and providing

superior adhesion and longevity.

3)

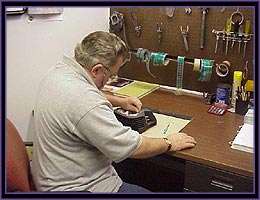

Prior to powder coating we carefully review our customers work

sheet and mask and plug all indicated surfaces, using special

high temperature silicone tape and plugs. This insures a professional

job.

4)

Next, we look for the best place to "hang" your part

before powder coating your finish so as to not show a hook mark.

Next, we look for the best place to "hang" your part

before powder coating your finish so as to not show a hook mark.

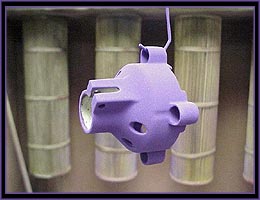

This is followed by "racking" your parts onto our

special baking racks prior to powder coating. The parts are then

"powder coated", with a special "powder coating

gun" that puts out around 90 kilovolts of charging voltage.

This causes the "powder" to pickup a

"positive charge" which needs to find

"ground". This "ground" is in our environmentally

controlled powder spray booth which has an

"earth" ground. This attracts the powder to the

"natural part".

We then carefully remove the parts from the spray booth being

careful not to touch the parts prior to the baking process.

(remember it is still in a baby like powder form).

5)

We then place the racks which are full of parts, into one of our

baking ovens. These oven are natural gas fired and use convection

heat to cure the "powder coating" at a range of

375-400 degrees F for 15-25 minutes.

We then place the racks which are full of parts, into one of our

baking ovens. These oven are natural gas fired and use convection

heat to cure the "powder coating" at a range of

375-400 degrees F for 15-25 minutes.

"Convection ovens" heat the air by "rolling"

the heat evenly around the part, allowing the part to be heated uniformly. This

is critical in properly curing the coating.

We also run 2 temperature sensitive laser guided heat guns to

make sure that the parts are at the correct cure temperature. These

guns are extremely accurate. Once we reach the

"bake time" we set our industrial timers for the

correct time.

6)

All parts exiting the ovens once cool, are followed by our

inspection process. Any parts that do not pass our strict

inspection, run back through our process for a recoat. note):

some products made of poor quality materials may show less then

perfect results. We will do everything we can to minimize these

problems. You may be advised to put your part in a textured

finish which will hide many flaws!

7)

After inspection, all of the parts are removed from our baking

racks and sent to our packing area where we carefully remove the

tape and plugs. We then clean all surface areas to remove any

glue from masking, debur any powder from the plug areas and wrap

your parts for shipment by U.P.S, or customer pick up.

About

Us | The Process | Gallery

| Prices | Colors | Contact

Us | Home

Follow

us on Facebook

12 Kendrick Road Unit 9

Wareham, MA 02571

Phone: 508-295-5601

Fax: 508-295-0403

Email

|